A little bit about us…

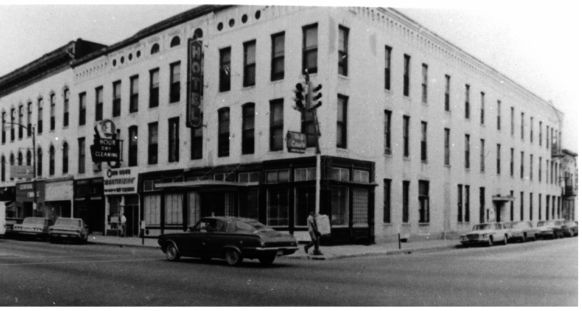

One Hour Cleaners was started as One Hour Martinizing Cleaners, the first week of April, 1958. It was located in the Bearss Hotel building, now the site of the City Hall. In 1979 when the Bearss Hotel (then called Peru Motor Lodge) was sold and the new owners were going to raze the building, One Hour Cleaners moved into their new permanent location at the corner of 3rd and Miami Streets.

One Hour Martinizing was a franchise that spread through out the country in the 1950’s and 1960’s. It offered one hour service at no extra charge. The cleaners of the day were large plants that cleaned in petroluem (instead of a synthetic solvent), and had drop stores meaning that one hour and same day service was not possible. Mr. Martin developed equipment and a process using this new synthetic solvent to offer one hour service and that cleaners could be located anywhere. Because of the fire hazard associated with petroluem, they could not be located in many parts of a town. In the heyday of “martizining”, it seemed every town had one. We dropped the franchise in the early 1970’s.

In November 1966, the cleaners was purchased by the Ralph Birk family and incorporated as BDC Enterprises, Inc. We are the only cleaners now in town who has not had a change in ownership for over 53 years. And every cleaners now in town has moved at least once.We moved to our present location in 1979.

The drycleaning industry was hit hard in the late 1960’s and early 1970’s with the polyester revolution, and locally, the industry was hit hard with the departure of the “Hustler” at Grissom Air Force Base. In the 1980’s there was a resurgence back to natural fibers in silks, rayons and wools. Also in the 1960’s came “coin-op” drycleaning. This was usually done in an 8lb machine, and the results many times produced dingy and smelly garments due to lack of proper solvent maintenance. While the same solvent is used over and over again, it needs to be filtered for insolubles, for dye removal, and distilled to make it pure. These little machines did not do this, and the results were obvious. Years ago, both Peru and Maconaquah bands used to let their students take their white wool uniform parts to “anybody” for cleaning. Some went to a professional drycleaner who properly maintained their solvent, some went coin-op, etc. and the result was that you had 100 shades of white wool (more like white, gray, yellow).

Our staff continually receives training from our affiliation with Drycleaning and Laundry Institute and Midwest Drycleaning and Laundry Institute. One member of our staff has received specialized training in wetcleaning, leather cleaning and wedding gown processing. We are the only cleaners in the area to have a Certified Garment Care Professional on staff and the first cleaners in Indiana (and 7th in the nation) to have such.

If you add up all our staff (part time and full time) experience and years in fabricare, it exceeds well over 100 years. One member of our staff served for nearly 10 years on the state drycleaning association and was President of the state drycleaning and laundry association.

Our finishing staff has attended various training seminars also. All this helps give you the best possible results. However no cleaner can guarantee that the manufacturer properly selected components that meet their care label instructions for cleaning. Only they can through proper testing. An example of this, is where they put fabric that can only be drycleaned with trim that can’t withstand drycleaning. And no cleaner can guarantee that every spot can be removed. But with proper training, proper equipment, proper chemicals, many spots can be removed. The best thing the consumer can do is not try to remove it themselves, as many times this can set the stain.

I recall few years back, a man who got gum on the seat of his expensive linen trousers. He tried all the tricks including a razor blade in which he actually cut many of the fibers, making a hole. With the application of one spot removal chemical, and steam, the gum was completely removed, yet his attempts actually ruined his trousers.

Today, a second generation of the Birk Family operates the drycleaners. Chris Birk is the president of BDC Enterprises Inc. (One Hour Cleaners). He holds certifications as CED (Certified Environmental Drycleaner), CPD (Certified Professional Drycleaner) and CPW (Certified Wetcleaner) which earns him the CGCP (Certified Garment Care Professional) title.